Steel House Production Stages

Steel House Production Stages

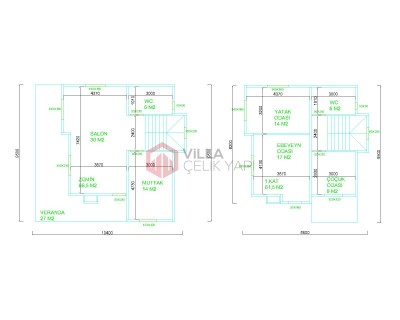

Stage 1:

First of all, we design steel villas, steel houses or prefabricated villas, prefabricated houses in line with your wishes, and design and present the most suitable structure for you. We design the building as a prefabricated or steel structure in accordance with the regional conditions.

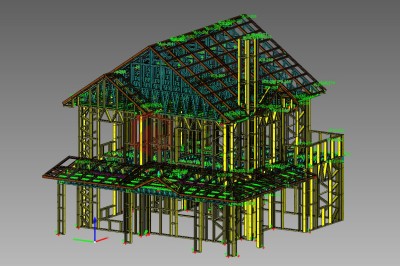

2nd Stage:

Steel construction or prefabricated structure, pre-manufactured in the factory, produced by computer-controlled machines with millimeter precision ; Our structures consisting of Wall panels, Truss panel, Ceiling panel, Roof panel and carrier columns. It is shipped to the construction site after it is combined with a rivet or bolt system and prepared.

3. Stage :

They reveal the steel skeleton by installing the panels, the main carrier system, which are made ready for assembly in our factory in a short time by our experienced and experienced personnel. Combination of smart screw or bolt is used. Thanks to the mounting on bolts and self-tapping screws, the resistance against earthquakes increases. No cracks occur in the impacts of the earthquake.

4th Stage :

After the installation of the steel building; The process of dressing the building exterior and interior pockets begins. Electrical and installation works are completed. Building cladding materials are determined at the time of order and building cladding is finalized with materials suitable for climatic conditions. Rockwool is definitely preferred for building insulation walls. Roof insulation is made with 10 cm thick mineral wool. The final coating can be done after 11 mm osab and membrane application is applied on the roof covering. (example: Single, Trapezoidal, Metal Tile or Nomal tile etc.)

5th Stage :

span style="background-color: #ffffff; color: #848494; font-family: open sans,sans-serif; font-size: 14px;">On the exterior walls, puttying or plastering is applied by first priming the selected material. Paint is applied as a final coat. Mesh grout plaster is applied to the joints of the inner walls. After the rough plaster is finished, three snow satins are drawn. After the inner wall is completely primed, it is finished with papier-mâché and finally paint carving.

6th Stage :

It is finished on wet floors and patio floors in line with your request and by applying the ceramic of your choice.

Stage 7 :

Finally, the finishing works for the building are completed. Doors, windows, parkas, sanitary ware, etc. are made and delivered in accordance with technical specifications.

First of all, we design steel villas, steel houses or prefabricated villas, prefabricated houses in line with your wishes, and design and present the most suitable structure for you. We design the building as a prefabricated or steel structure in accordance with the regional conditions.

2nd Stage:

Steel construction or prefabricated structure, pre-manufactured in the factory, produced by computer-controlled machines with millimeter precision ; Our structures consisting of Wall panels, Truss panel, Ceiling panel, Roof panel and carrier columns. It is shipped to the construction site after it is combined with a rivet or bolt system and prepared.

3. Stage :

They reveal the steel skeleton by installing the panels, the main carrier system, which are made ready for assembly in our factory in a short time by our experienced and experienced personnel. Combination of smart screw or bolt is used. Thanks to the mounting on bolts and self-tapping screws, the resistance against earthquakes increases. No cracks occur in the impacts of the earthquake.

4th Stage :

After the installation of the steel building; The process of dressing the building exterior and interior pockets begins. Electrical and installation works are completed. Building cladding materials are determined at the time of order and building cladding is finalized with materials suitable for climatic conditions. Rockwool is definitely preferred for building insulation walls. Roof insulation is made with 10 cm thick mineral wool. The final coating can be done after 11 mm osab and membrane application is applied on the roof covering. (example: Single, Trapezoidal, Metal Tile or Nomal tile etc.)

5th Stage :

span style="background-color: #ffffff; color: #848494; font-family: open sans,sans-serif; font-size: 14px;">On the exterior walls, puttying or plastering is applied by first priming the selected material. Paint is applied as a final coat. Mesh grout plaster is applied to the joints of the inner walls. After the rough plaster is finished, three snow satins are drawn. After the inner wall is completely primed, it is finished with papier-mâché and finally paint carving.

6th Stage :

It is finished on wet floors and patio floors in line with your request and by applying the ceramic of your choice.

Stage 7 :

Finally, the finishing works for the building are completed. Doors, windows, parkas, sanitary ware, etc. are made and delivered in accordance with technical specifications.

- Address :Saray Mahallesi Keresteciler Sitesi Adnan Menderes Bulvarı No:26 Kazan / Ankara

- Phone :+90(312) 378 79 78 - +90 (554) 584 08 78

- Email :satis@villacelik.com